Remote Control of Electrolysis Plants

ITI Group has been awarded numerous contracts by a large manufacturer of hydrogen energy systems to design, supply and install control systems for various containerised water electrolysis plants located in the UK and overseas. In addition ITI Group provided a SCADA system which allows full local and web-based visualisation and control of electrolysis plants based on the client’s premises.

The ITI Group-designed systems provide:

- Holistic view of all production and commissioning plants.

- Smarter maintenance and diagnostics.

- Remote control of plants.

- Improved monitoring and analysis of production.

- Alarm and event distribution to remote uses (including mobile devices).

- Mobile access to plant data.

Our innovation

Fully integrated solution

TUV/CompEx certified engineering solution

Dedicated ITI team

Familiarity with the site and systems helped deliver the project on time and on budget

Solution

ITI Group’s extensive knowledge was utilised to provide process control and safety systems which satisfy the client’s specific user requirements. Each system had unique safety and control requirements which necessitated individual specification and design.

Each ITI Group solution adhered to the clients’ specific functional safety and hazardous area assessments. The design utilised Siemens

fail-safe PLC controllers and safety I/O modules with suitable SIL protection to meet a number of client defined Safety Instrumented Functions (SIFs). Intrinsically safe barriers were used to provide a safe interface to the hazardous area signals which originated in Zone IIC T4, and SIL safety contactors were used to isolate equipment under critical safety failure.

ITI Group’s SCADA system was based on a Siemens WinCC solution. It incorporated remote TCP/IP access to sites, duplication of plant screens for visualisation and control of each plant and historian functionality for data logging and analysis.

The ITI Group’s scope of supply included:

Full design compliance with Ex/ATEX requirements

Design of HMI Mimic/Control screens for each plant

Installation and full commissioning of the SCADA at the client’s premises

Full support, including additions of new plants

Control hardware specification, design, build and test at ITI premises

Specification, design and configuration of system architecture, based on Windows Server and Virtual Machines/Clients, using a range of Siemens WinCC utilities

Installation of the control panels into the containerised system, including all electrical and instrumentation connections throughout including CompEx certification

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

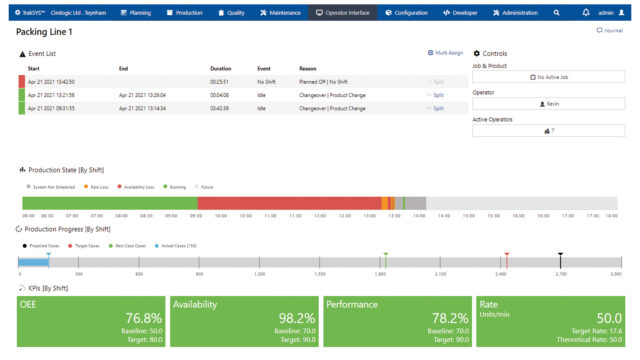

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?