Spirit already had AVEVA (formerly OSIsoft) PI System infrastructure in place and were keen to take better advantage of its capabilities.

Following conversations with ITI Group, who have supported the safety and control systems on their onshore and offshore assets for a number of years, Spirit embarked on three initial digital transformation projects which all quickly provided a positive return on investment. These rapid initial successes prompted the initiation of further super sprint structures and the collaborative delivery of business benefits to multiple areas of the company.

20 days and £10m lost production saved on just one pre-empted incident

Mobile/remote logging solution implemented

Ability to monitor Oil & Gas Industry Standard KPIs

Company-wide collaborative business transformation

Capability Maturity

Spirit Energy initially embarked on three target-specific projects, with the aim of addressing specific business-related goals. By first focusing on achieving immediate benefits within defined business units, the results could be validated, providing the confidence that rolling out projects across the whole company would deliver significant ROI.

Initial successes included:

PI Manual Logger

Readings from various field devices, such as temperature or pressure transmitters, had previously been recorded by engineers and then manually inputted into the PI System on return to the office. ITI provided a tablet-based, slimmed-down version of PI Vision to allow engineers to input data into the system directly, saving time, reducing duplication of effort and eradicating communication errors across shift changes.

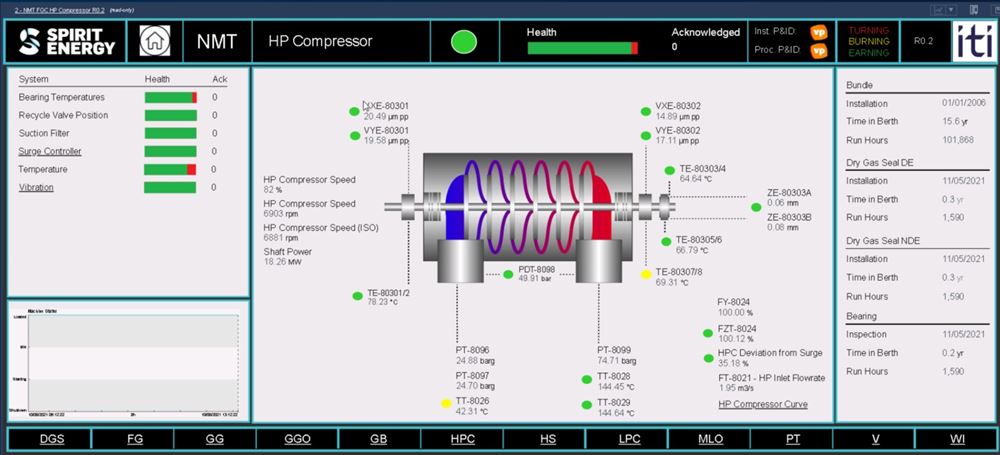

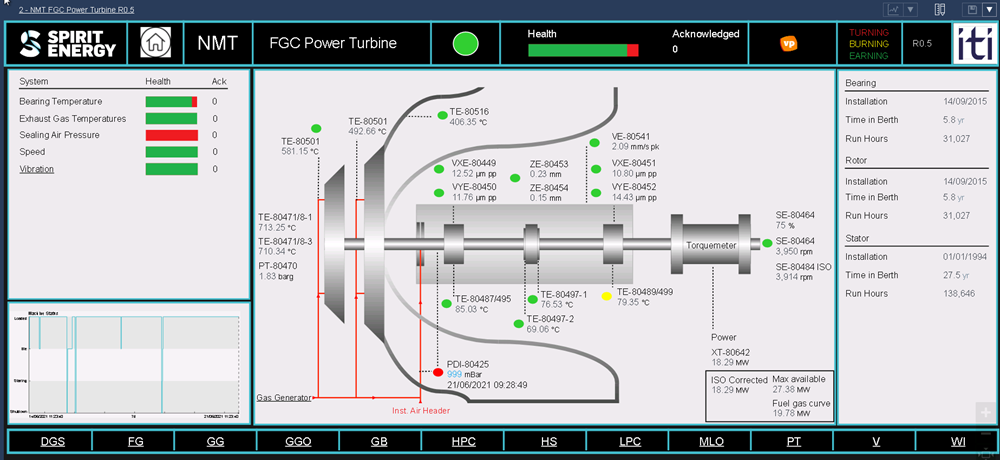

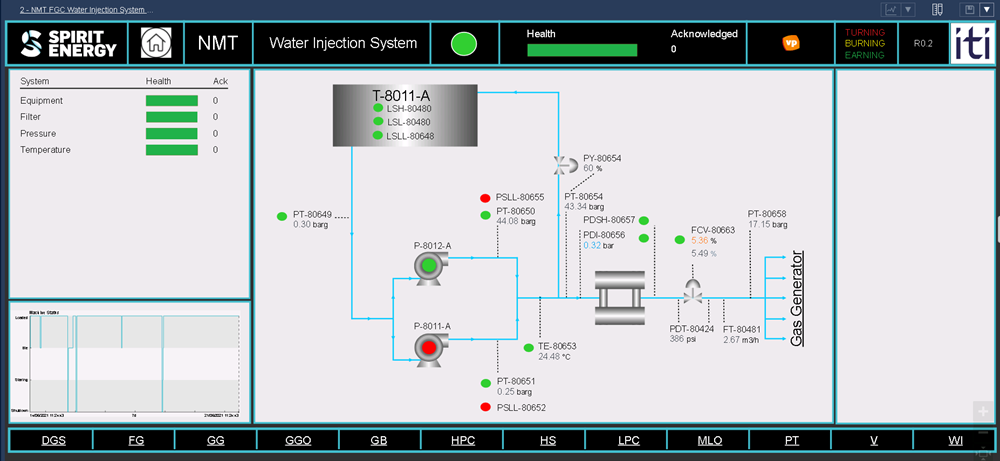

Condition-based Monitoring

Following ITI’s successful installation of a new cyber secure communications interface for the gas turbine systems at North Morecambe Terminal, the provision of data on the rotating equipment was vastly increased. In order to make best use of this data, ITI expanded Spirit’s existing PI AF database and PI Vision screens, optimising data storage, frequency, integrity, accuracy and completeness; providing more efficient analytics; and upgrading the resultant displays of real-time data to improve user experience and response time of maintenance engineers.

ROI was realised within just 9 months:

In one example, a 20-day unplanned shutdown was avoided due to improved monitoring, saving Spirit on average of £500k per day, or £10 million.

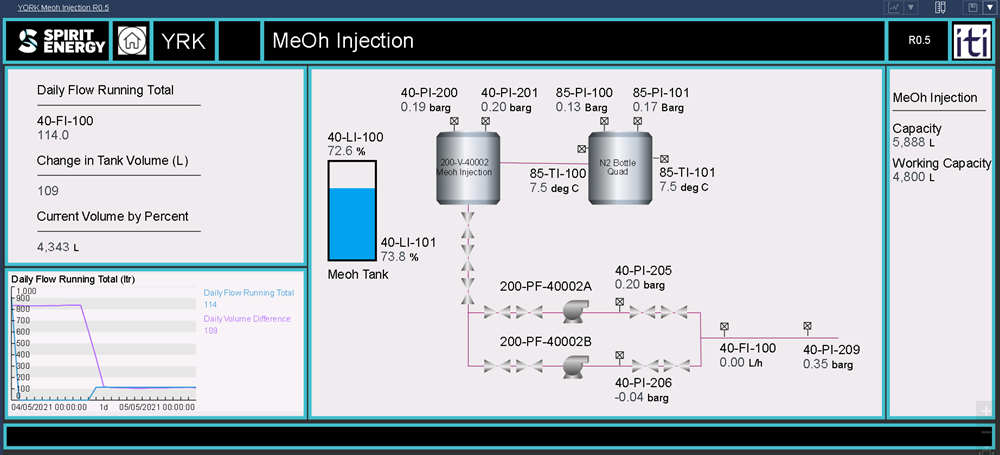

Flare and Blowdown Monitoring

ITI developed new flare monitoring and blowdown surveillance screens in PI Vision with a supporting database in PI AF.

These now allow Spirit to instantly and accurately monitor transmitter drift; a cumbersome process that had previously been undertaken using formulas in Microsoft Excel. The new system also incorporates alerts, and allows quick access to information on number of drifts, blowdowns and flaring events at various levels, from instrument, to system, to full asset.

“Digital transformation has already had a tremendous impact on our business…”

“…providing cost savings and enabling us to meet our targets. The potential for further returns is considerable, with carbon emissions targets top of that agenda.”

Glen Milne – Production Systems Manager, Spirit Energy

Roadmap for Future Development

Spirit Energy very quickly recognised the potential of an integrated Digital Transformation Strategy and the wider benefits across the whole company.

The successes of the initial stages will be rolled out across the rest of the business and the team has developed a roadmap for the upcoming stages in their digital transformation journey. By executing the work in a series of large sprints, Spirit Energy will be able to cover more areas and maximise the benefits at each stage.

Aspects of their operations already highlighted for transformation include monitoring for heat exchangers, control valves, fuel gas usage, field flowrates, wells, field gas compressors and production gas compressors.

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

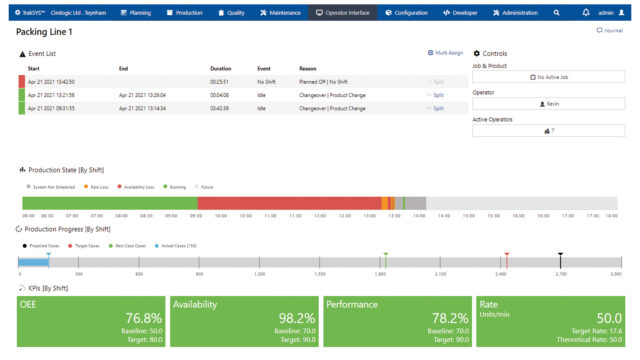

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?