One such project saw the upgrade of the obsolete safety equipment on the DPPA platform, completing a series of fire and gas system (FGS) and emergency shutdown (ESD) system upgrades on all the assets across Morecambe Bay.

Improved system reliability and minimised downtime

Reduced maintenance and proof testing requirements

Reduced spares holding through system consistency across the field

Minimised Downtime

The new systems are not only more reliable, but by simplifying the technology, diagnosis times of now unlikely issues are greatly reduced.

Since DPPA is a processing platform, the programme of works also had to minimise disruption to routine operation in order to avoid affecting production from adjacent fields.

The Old Systems

Centrica had identified that the existing GE Fanuc 90/30 programmable logic controller (PLC)-based emergency shutdown (ESD) and fire and gas safety (FGS) systems utilised obsolete technology.

They also incorporated complex and unreliable hardwired back-up relay systems and operator interface matrices for status indication and test functionality, making them maintenance intensive and liable to calibration drift, causing loss of production through unplanned platform shutdowns.

Integrated Solution

ITI Group provided a new GE-based ESD system supplied on backplanes so that it could be directly mounted into the existing offshore control room cabinets.

The new GE-based FGS, which included Simtronics, Honeywell, Det-tronics and Siemens gas, flame and smoke detection devices, was built and housed in new cabinets provided by ITI Group.

Both systems were hardwired into existing platform equipment and interfaced with the existing distributed control system (DCS) as well as remote systems on neighbouring platforms. ITI also provided a new Wonderware InTouch based HMI for operator interfacing, providing historical alarms, events and data plus access to sequence-of-events recording, inhibit and override control.

Flexible Installation Programme

Following a detailed design phase, ITI Group first began installation and pre-commissioning of the new fire and gas detection devices in May 2016, followed by installation of the new emergency shutdown system in August, all in line with client shutdown schedules. From initial isolation and destruct to Lloyds verification testing and sign-off, actual downtime amounted to just three weeks.

The obsolete equipment was then decommissioned and deconstructed during scheduled intervention windows over the next six months.

Field-wide Deployment

The solution was based on the same, proven systems that ITI Group previously deployed across all the other assets in Morecambe Bay, providing consistency for maintenance and operator understanding, plus uniformity of spare parts.

Ongoing Support

ITI Group continues to provide ongoing system support and maintenance to Spirit Energy’s Morecambe Bay onshore and offshore assets. As well as holding a supply of spares specifically for the Morecambe Bay systems, ITI Group provides Spirit Energy with regular scheduled site inspections and 24 hour on call service.

How we’ve helped other businesses like yours

Sellafield FGMSP Digital Twin and 3D Planning Tool

ITI Group worked with Sellafield to create a digital twin of the FGMSP, plus an integrated 3D interactive planning tool, to determine the most effective sequences for waste removal based on a myriad of interdependencies.

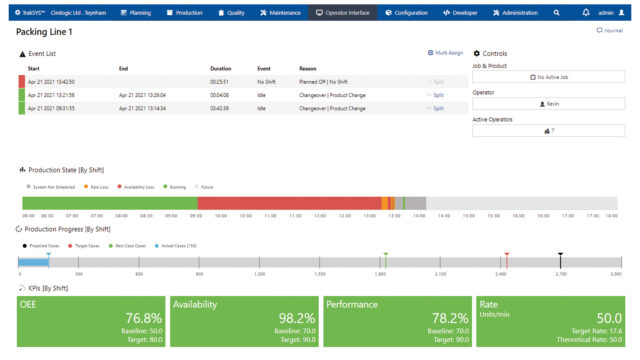

Purity Soft Drinks Achieved Efficiency Improvements of 20%

Leading soft drinks manufacturer achieves OEE efficiency gains and data insight to drive continuous improvement from real-time OEE platform.

Spirit Energy Digital Transformation

After just one year of collaborating with ITI Group on their Digital Transformation programme, Spirit Energy are already seeing the benefits of a properly managed data solution.

How can we help you?