How do you manage the flow of materials throughout the value chain?

How do you maintain control of inventory to increase production efficiency and reduce working capital requirements? Maintaining inventory accuracy, optimising budgets and spending, and streamlining production planning is essential to increasing production efficiency.

TrakSYS MES Brochure

Download the brochure to learn more about the capabilities of the TrakSYS™ MES platform and how it can help your organisation embrace digital manufacturing.

Learn more

Inventory Solution

Built on the MES TrakSYS™ platform from Parsec Corp, ITI Group’s (formerly Cimlogic) Inventory solution gives manufacturers real-time insight into material status and location through warehousing, production, and distribution:

- Manage inventory: from raw material warehousing to finished goods more effectively using real-time production and ERP data

- Raw Materials & Work-in-Process: gain full visibility of material locations, statuses, and interruptions in material flow. Reduce delays caused by inventory queues which are often a result of inadequate communication

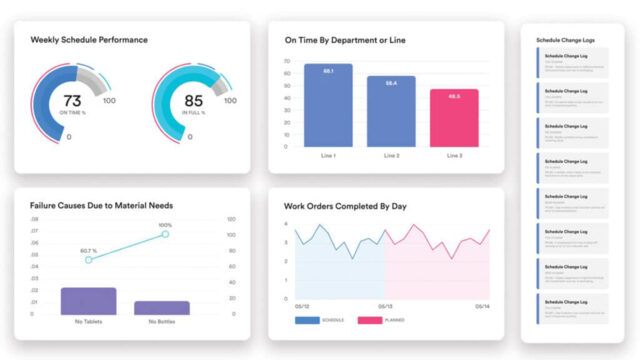

- Production Planning & Scheduling: plan and schedule human and machine resources, to fully utilise the available time of workforce and equipment. Track schedule compliance, changes and reasons

- Finished Goods: determine quantities required to fulfil orders. Real-time exception reporting for late and partial quantities. Stock-out predictions based on usage patterns

- Material traceability: track materials throughout production, including supplier, lot code, process route, employee touches, dates/times, quality test results, process parameters, etc

- Gain visibility into scheduling & warehouse inventory metrics: improve inventory accuracy, monitor supply chain quality/performance and reduce inventory write-downs to quickly determine areas of the process that require corrective action to decrease order-to-ship lead-times and improve on-time delivery performance

More in Manufacturing Execution Systems

View our Case Studies