How do you ensure optimal quality to protect consumer safety, brand reputation and bottom line?

Achieving end-to-end traceability in a production environment is critical to protecting consumer safety and your organisation’s brand reputation. Consumers are increasingly demanding transparency and information about the products they purchase, from raw materials to the finished item. How can manufacturers monitor the quality of raw materials, components, and finished products at every stage of production to help identify defects or deviations early in the process, to minimise the risk of faulty products reaching the end-user?

Track & Trace Solution Brochure

Track & Trace Solution

Built on the MES TrakSYS™ platform from Parsec Corp, ITI Group’s (formerly Cimlogic) Track & Trace solution gives manufacturers enterprise-wide traceability to prevent product recalls, increase quality and optimise inventory management:

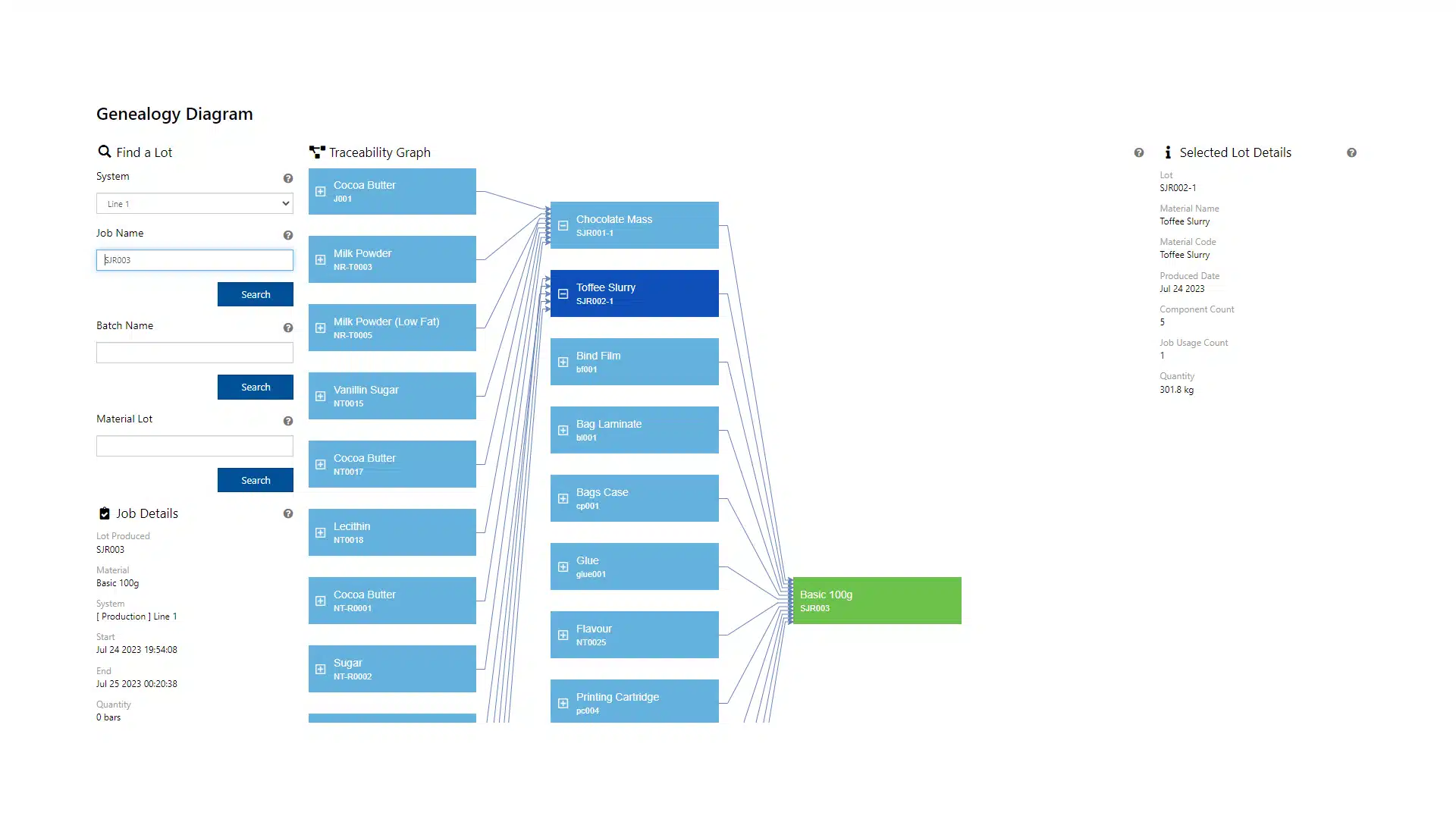

• Record, track, and trace the genealogy of raw materials, Work-in-Process (WIP), and go-to-market products to improve quality control and meet regulatory compliance

• Utilise traceability data for real-time transparency, to proactively limit the impact of quality issues before the product is shipped

• Replace paper-based systems with digital records to capture material and activities throughout the production lifecycle (forward and backward traceability)

• Effectively manage product recalls by identifying the affected products and their distribution points quickly to reduce downtime and production disruption

• Improve supply chain transparency and optimise inventory management to reduce lead times and streamline distribution processes for improved operational efficiency and cost savings

More in Manufacturing Execution Systems

View our Case Studies